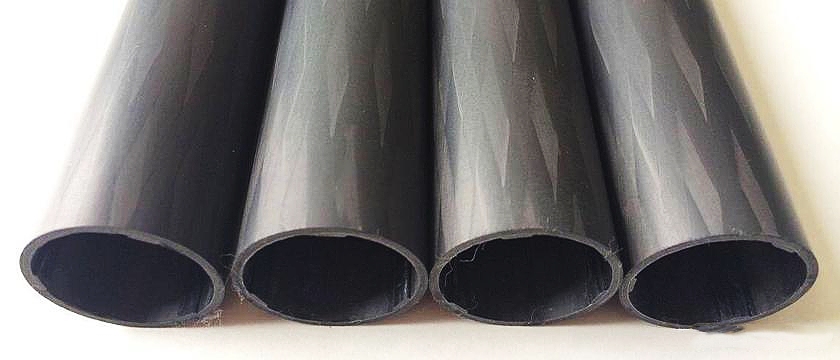

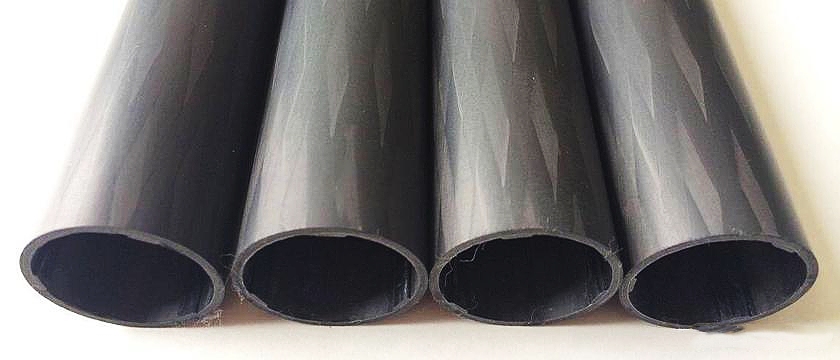

Advantages of GLX filament wound tubes:

(1) Best performance, thin wall thickest

Due to the different winding angles of carbon fiber, the best balance among tensile strength, circumferential compressive strength and torsional strength is achieved. Combined with the tension advantage of carbon fiber yarn, the pipe can not only achieve the expected strength requirements, but also control the wall thickness to the best.

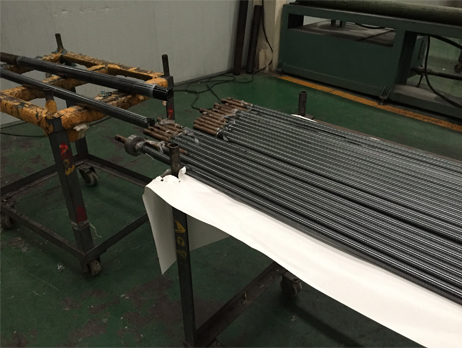

(2) Automatic production, stable quality

The tension of the carbon fiber, the resin - fiber ratio, and other variables are controlled by a computer. Its stability and accuracy are more accurate than manual operation, which makes the wall thickness, flatness, density, strength and other aspects of the finished product can achieve the desired effect.

(3) Strong structural design

Because the winding angle of carbon fiber yarn can be accurately controlled, the winding angle of carbon fiber directly affects the circumferential compressive strength and tensile strength of the pipe. Therefore, the winding process can play a better design space and help according to the performance requirements of the product. This is also the reason why the filament wound pipe fittings are paid more and more attention in the industrial field. For example, large mechanical rollers, automotive transmission shafts, yacht masts, large power poles, and aerospace industry accessories.

碳纤缠绕的优点:

(1)最佳性能,最薄壁厚

由于管材采用了不同的碳纤维缠绕角度,因此在抗拉强度、环向抗压强度和抗扭强度之间实现最佳的平衡点。结合碳纤维丝的张力优势,管材既能达到预期的强度要求,也能将壁厚控制至最薄。

(2)自动化生产,质量稳定

碳纤丝的张力,树脂/纤维的比例,以及其他变量,都是由计算机控制的。其稳定性和准确性比人工操作更加精准,这使得成品的壁厚、平直度、密度、强度等各方面都能达到预期效果。

(3)结构设计性强

由于碳纤丝的缠绕角度可以被精确控制,纤维的缠绕角度直接影响到管材的环向抗压强度和拉伸强度。所以,缠绕工艺能够根据产品的性能需求发挥更好的设计空间和帮助。这也是缠绕管件越来越被工业领域重视的原因。比如大型机械滚轴、汽车传动轴、游艇桅杆、大型电线杆、以及航天工业配件等。