LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Product Overview

Our pultruded carbon fiber profiles deliver unmatched strength, lightweight design, and durability. Available with vinyl ester or epoxy resin, they offer tailored properties for diverse applications.

The pultrusion process enables virtually unlimited lengths and versatile cross-sectional shapes. Long profiles provide excellent flexibility and bending performance, while shorter sections offer strong support and elasticity.

Cost-effective compared to other carbon fiber manufacturing methods, these profiles are ideal for model aircraft, sporting equipment reinforcements, lightweight guide rails, and more—combining high performance, reliability, and value in a single solution.

(1)Materials

• Standard continuous unidirectional carbon fiber with vinyl ester resin (corrosion-resistant); optional epoxy or specialty resins for enhanced insulation and chemical resistance

(2)Advantages

• Pure unidirectional fiber for exceptional tensile and bending strength

• Lightweight, high-strength, and producible in virtually unlimited lengths

• Flexible mold use: same mold can produce rods and tubes of the same profile

| Regular Shape |

|---|

|  |  |  |

|---|---|---|---|

| Carbon Round Tube | Carbon Solid Rod | Carbon Square Tube | Carbon Square Solid Rod |

| Note: With adequate cross-sectional space, pultruded profiles of the same dimensions can be manufactured as either hollow tubes or solid rods through appropriate die design. |

|---|

(3)Specs & Options

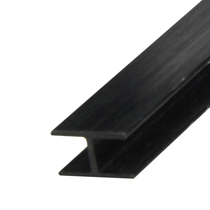

• Shapes: Rods, tubes, I-beams, C-channels, trapezoids, flat strips, oval tubes, and more

• Length: Standard 1000 mm, customizable; theoretically unlimited

• Color: Black (natural carbon fiber)

| Regular Shape |

|---|

|  |  |  |

|---|---|---|---|

| Carbon Square-Round Tube | Carbon Rectangular Tube | Rectangular-Round Tube | Rectangular Solid Rod |

|  |  |

|---|---|---|

| Carbon Fiber Strip / Flate | Semicircle Solid Rod | Double-cell Rectangular Tube |

| Note: With adequate cross-sectional space, pultruded profiles of the same dimensions can be manufactured as either hollow tubes or solid rods through appropriate die design. |

|---|

(4)Carbon Fiber Vinyl Ester Resin vs Epoxy Resin Pultruded Profiles

Physical & Chemical Performance Comparison

• Vinyl ester pultruded profiles

Offer excellent corrosion resistance, reliable mechanical performance, and outstanding cost efficiency for most industrial and outdoor applications.

• Epoxy pultruded profiles

While more expensive to manufacture, are the preferred solution for high-performance applications that demand superior strength, fatigue resistance, and long-term dimensional stability.

| Comparison Item | Carbon Vinyl Ester Pultruded Profiles | Carbon Epoxy Pultruded Profiles |

| Tensile Strength | High (meets most industrial and structural requirements) | Higher (better utilization of fiber ultimate strength) |

| Flexural Strength / Stiffness | Good | Higher stiffness and flexural modulus |

| Compressive Strength | Good | Superior |

| Shear Strength | Good | Superior |

| Fatigue Resistance (Cyclic Load) | Medium to good | Excellent, suitable for long-term dynamic loading |

| Creep Resistance (Long-term Load) | Good | More stable with lower deformation |

| Dimensional Stability | Good | Excellent, ideal for high-precision structures |

| Weight / Density Impact | Lightweight | Lightweight (similar to vinyl ester) |

| Acid Resistance | Excellent | Good |

| Alkali Resistance | Excellent | Good |

| Salt Spray / Marine Resistance | Excellent | Good |

| Overall Chemical Resistance | Very strong (key advantage) | Medium to strong |

| Hydrolysis Resistance | Excellent, suitable for humid environments | Medium to good (depends on formulation) |

| Weather Resistance (Outdoor Use) | Excellent, long-term stability | Good |

| Service Temperature Capability | Medium to high | Higher heat resistance |

| Pultrusion Production Efficiency | High (fast curing, ideal for continuous mass production) | Lower (slower curing, higher process requirements) |

| Production Stability / Yield Rate | High | Medium |

| Unit Production Cost | Lower / cost-effective | Higher |

| Typical Application Environment | Corrosive, outdoor, industrial structures | High-strength, high-precision, fatigue-critical applications |

| Custom Shape |

|---|

|  |  |  |

|---|---|---|---|

| Special Shape | Carbon I Bar | Carbon Trapezoidal tube | Double-cell Carbon Elliptic Tube |

| Note: You may provide a CAD drawing of the required cross-section based on the actual application needs of your product, and we can design and manufacture a custom pultruded profile exclusively for you. |

|---|

(5)Primary Applications

| Carbon Vinyl Ester Pultruded Profiles are ideal for | Carbon Epoxy Pultruded Profiles are ideal for |

| Chemical processing equipment and support structures | Aerospace and UAV structural components |

| Outdoor and humid environment applications | High-end sports and performance equipment |

| Marine, salt spray, and highly corrosive conditions | Applications with long-term dynamic or fatigue loading |

| Large-volume, standardized industrial profiles | High-precision equipment structures |

| Cost-sensitive projects | Projects requiring superior dimensional stability and mechanical performance |

eg.:

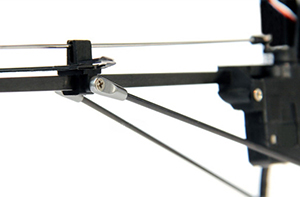

• RC models & drones: pushrods, landing gear, struts, and structural reinforcement

• Outdoor & sporting goods: kite spines, tent poles, flagpoles, tennis racket frames, flex poles

• Agriculture & aquaculture: greenhouse framing, marine farming structures, desalination equipment

• Industrial & automation: corrosion-resistant conveyor components, antenna masts, electroplating racks

• Construction & civil engineering: temporary supports, lightweight framing in aggressive environments

• Electronics & telecommunications: antenna tubes, EMI-shielding supports

|  |  |

|---|---|---|

| Kite Spines | Boat Support | RC Model parts |

All profiles are continuously pultruded for void-free consolidation, high fiber volume fraction, and exceptional lot-to-lot consistency. Custom cross-sections, dimensions, and resin formulations are available with low minimum order quantities and short lead times.

Need ultra-strong, ultra-light, and completely corrosion-proof linear profiles? Send us your section drawing or performance requirements – we’ll reply with a detailed proposal within 24 hours.