LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Product Overview

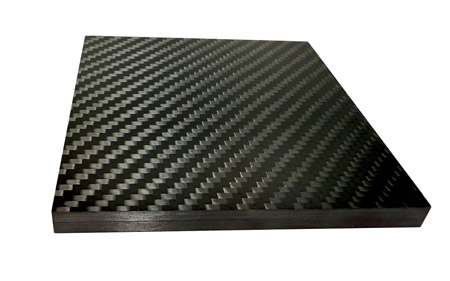

We manufacture carbon fiber plates / sheets using two proven processes: compression molding and autoclave curing, allowing us to meet a wide range of performance requirements.

Carbon fiber sheets find applications across civilian products and high-end aerospace / defense sectors. We tailor ply schedule, fiber grade, and resin properties (fatigue resistance, temperature tolerance, corrosion resistance) to each specific use case.

For strength-critical applications, we recommend compression molding. For parts requiring superior surface finish or larger dimensions, autoclave processing is the preferred choice. Surface materials are primarily cosmetic and can be customized to your specifications.

Details on our Weave carbon fiber sheets follow below.

(1)Material System

• 100% carbon fiber reinforcement combined with a toughened epoxy resin matrix.

• Surface plies: 3K plain / Twill woven fabric / Forged carbon / Spread Tow Woven Fabric

• Core plies: Unidirectional carbon fiber for optimized strength and stiffness

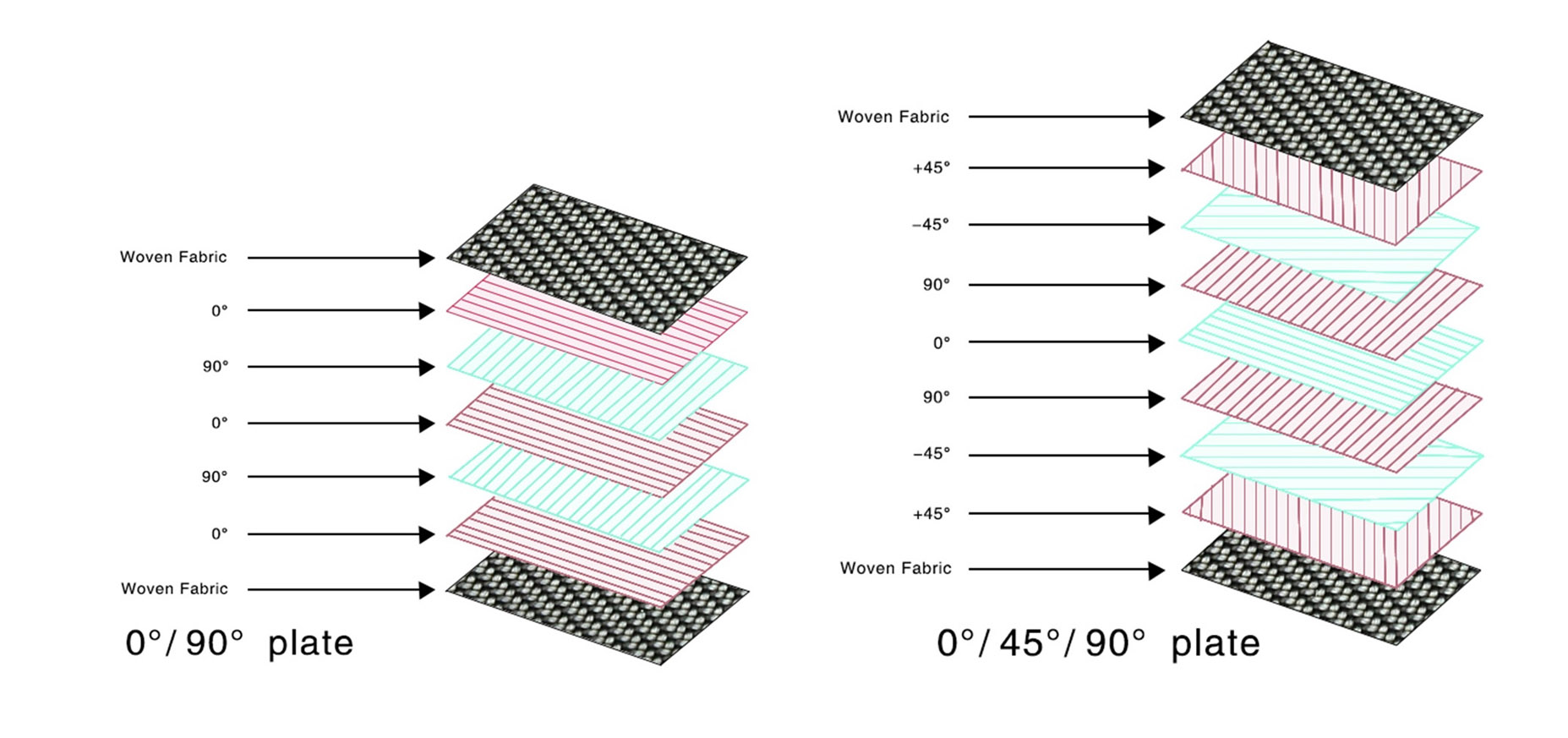

(2)Standard Layup Configurations

• 0°/90° (balanced, highest bending stiffness)

• 0°/±45°/90° (good torsional resistance)

(3)Available Specifications

• Thickness: 0.5 / 1.0 / 1.5 / 2.0 / 2.5 mm … up to 10 mm and thicker

• Thickness tolerance: ±0.1 mm

• Standard sizes: 500 × 400 mm 500 × 500 mm 500 × 600 mm

• Special Size: By Autoclave Processing Max 1000 x 2400mm, by Compression Molding Max 1000 x 1500mm

• Surface finish: Gloss / Satin / Matte

• Pattern: Plain / Twill / Forged Carbon / Spread Tow Woven

|  |

|---|---|

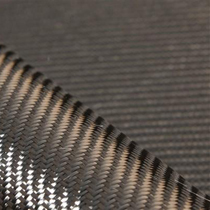

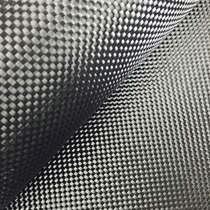

| Carbon Plates With Twill Woven | Woven Carbon Plate with Thick thickness |

(4)Key Performance Advantages

• Exceptional strength-to-weight ratio – typically 1/3 to 1/4 the weight of aluminum plate at equivalent thickness while delivering 3–4 times the specific stiffness

• Outstanding corrosion and chemical resistance (acids, alkalis, solvents)

• High impact resistance and excellent fatigue performance

• Good thermal stability – continuous service up to 120 °C (higher-Tg systems available)

• Superior EMI shielding properties due to conductive carbon fiber network

• Easily machined (CNC routing, waterjet, drilling) with standard carbide tooling

|

|---|

|  |

|---|---|

| Gloss / Satin / Matte Finish | UD Carbon Fiber Plate |

(5)Primary Applications

• Competition RC vehicles: chassis plates, skid plates, suspension components

• FPV & professional drones: frames, arms, mounting plates

• Industrial automation: robot end-effectors, machine guards, lightweight fixtures

• Precision instrumentation: base plates, enclosures, structural panels

• Sporting goods: bicycle components, hockey stick blades, golf club heads

• Electronics: EMI/RFI shielding enclosures and internal supports

• Aerospace & automotive: interior panels, brackets, secondary structural elements

• Infrastructure reinforcement: carbon fiber laminate bonding for concrete/steel strengthening (unidirectional grades)

|  |

|---|---|

| Drone Frames | Bicycle Components |

All sheets are compression-molded under precisely controlled heat and pressure to ensure void-free consolidation, consistent mechanical properties, and excellent surface quality.

Custom thicknesses, layups, colors (via colored glass or forged carbon surface), and machined-to-print parts are available with short lead times.

Need a lightweight, ultra-stiff, corrosion-proof solution? Send us your performance requirements and we’ll deliver ready-to-use carbon fiber sheets that outperform metal at a fraction of the weight.

|  |  |  |

|---|---|---|---|

| Twill Woven | Plain Woven | Forged Carbon | Spread Tow Woven |

| You can Sellect the materials as your carbon plate surface above. |

|---|