LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Product Overview

We manufacture carbon fiber plates / sheets using two proven processes: compression molding and autoclave curing, allowing us to meet a wide range of performance requirements.

Carbon fiber sheets find applications across civilian products and high-end aerospace / defense sectors. We tailor ply schedule, fiber grade, and resin properties (fatigue resistance, temperature tolerance, corrosion resistance) to each specific use case.

For strength-critical applications, we recommend compression molding. For parts requiring superior surface finish or larger dimensions, autoclave processing is the preferred choice. Surface materials are primarily cosmetic and can be customized to your specifications.

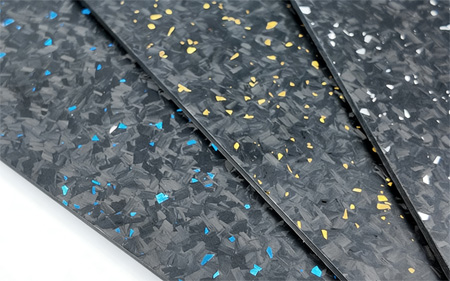

Details on our forged carbon fiber sheets follow below.

(1)Material System

• Surface layer: Forged carbon fiber prepreg; metallic flake (gold, silver, red, blue, green, purple) or vivid transparent colored resin Pregreg (red, yellow, blue, green, purple, gunmetal) can be incorporated directly into the surface resin

• Inner layers: Unidirectional carbon fiber prepreg + high-performance toughened industrial-grade epoxy resin

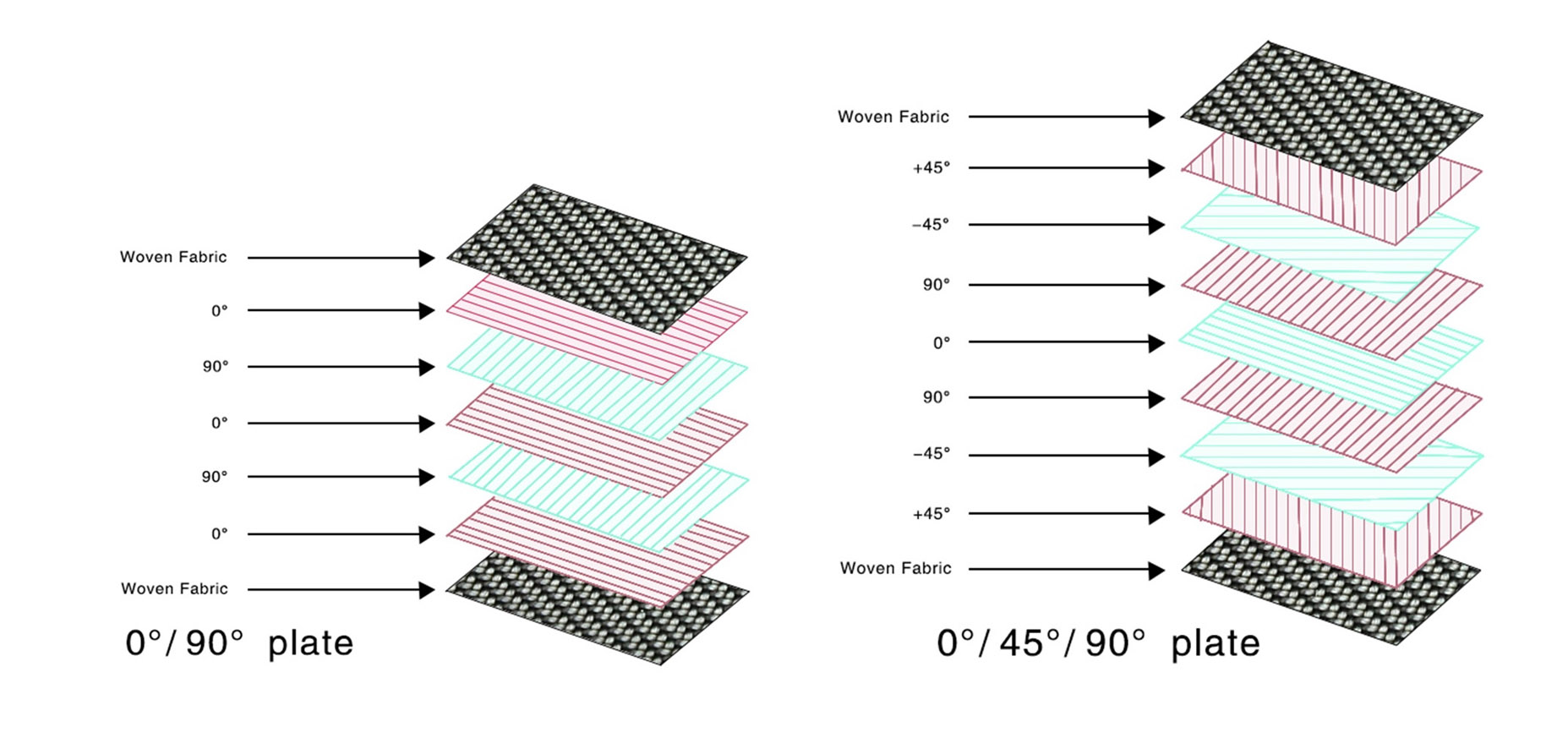

(2)Construction Features

• Forged carbon pattern on surface

• Optional metallic-flake or colored-resin for surface finish

• 0°/90° (balanced, highest bending stiffness)

• 0°/±45°/90° (good torsional resistance)

• Mechanical properties approximately 90–95 % of weave carbon sheets

(3)Standard Specifications

• Thickness: 0.5 / 1.0 / 1.5 / 2.0 / 2.5 mm … up to 10 mm and thicker

• Thickness tolerance: ±0.1 mm

• Standard sizes: 500 × 400 mm 500 × 500 mm 500 × 600 mm

• Special Size: By Autoclave Processing Max 1000 x 2400mm, by Compression Molding Max 1000 x 1500mm

• Surface finish: Gloss / satin / matte

• Appearance options:

• Metallic-flake series (gold, silver, red, blue, green)

• Colored-resin series (red, yellow, blue, green, purple, orange, gunmetal)

|  |

|---|---|

| Colerd Forged Carbon Plate | Forged Carbon Plate with metallic flake |

(4)Key Advantages

• Flake/pigment is fully integrated into the resin during cure – highly resistant to abrasion, UV, and scratching

• Extremely lightweight – over 60 % lighter than same-thickness aluminum

• High strength and high stiffness

• Excellent impact resistance, fatigue life, corrosion resistance, and UV stability

• Easily machined via CNC routing, drilling, and waterjet cutting

|

|---|

| UD carbon Fiiber Layup of Plate |

(5)Primary Applications

• Supercar & aftermarket automotive: center consoles, door cards, steering wheel trim

• Luxury goods: watch cases, pens, knife handles, jewelry boxes

• Flagship consumer electronics: phone frames, laptop lid (A-cover), headphone shells

• High-end drones & RC models: cosmetic covers

• Gaming/esports peripherals: keyboard top plates, mouse shells, monitor arms

• Professional photography gear: quick-release plates, gimbal accents

• Display models & art installations