LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Product Overview

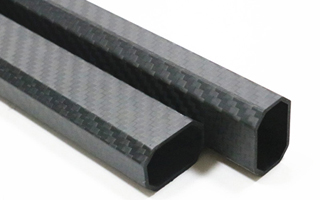

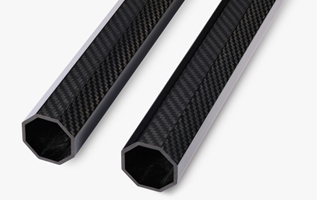

We utilize advanced compression molding technology to produce a variety of polygonal tubes, including commonly used shapes such as square, rectangular, hexagonal, and octagonal tubes. Custom shapes can also be tailored to specific requirements. The combination of compression molding and carbon fiber structure results in products with higher density and lower weight. Compared to traditional roll wrapped tubes, compression-molded tubes offer significantly enhanced strength. This process ensures excellent mechanical performance, meeting the demands of high-strength applications. In addition to polygonal tubes, we also manufacture circular, elliptical, and other custom-shaped tubes through the same molding process, expanding the range of applications.

Polygonal tubes are typically used in high-strength applications such as robotic arms, drone arms, and components designed to prevent rolling, among others. Below is a detailed introduction to our custom-shaped tube products:

(1)Material Composition

• Outer Layer: 3K/6K/12K twill / plain woven carbon fiber prepreg, carbon fiber + aramid fiber hybrid, forged carbon fiber, and stretch carbon fiber fabric

• Inner Layer: Unidirectional carbon fiber prepreg

• Resin: Industrial-grade toughened epoxy resin

(2)Structural Features

• Polygonal cross-sections (square, rectangular, hexagonal, octagonal, elliptical, and other custom shapes)

• Multi-directional unidirectional carbon fiber layup for the inner layer + woven fabric for the outer layer

• Smooth transitions at sharp corners, no seams or wrinkles, ensuring high surface quality

• Compared to roll-winding and autoclave processes, compression-molded tubes have a higher density but lighter weight

|  |  |

|---|---|---|

| Square Tube | Rectangular Tube | Hexagonal Tube |

(3)Standard Specifications

• Cross-sections: Square, rectangular, hexagonal, octagonal, and other custom shapes

• Standard Length: 500 - 1000 mm

• Tolerances: Outer dimensions ±0.15 mm, wall thickness ±0.1 mm

• Surface Finish: Glossy / Matte

• Appearance Options: Plain woven / Twill woven / Forged carbon fiber random woven / Carbon fiber + aramid hybrid / Stretch wide woven

(4)Key Performance Advantages

• Superior compressive, torsional and bending strength – outperforms equivalent aluminum sections

• Supper lighter – only ~1/5 the weight of steel and ~60 % of aluminum at the same volume

• Excellent impact resistance and outstanding fatigue life

• Fully corrosion-proof, UV-stable, acid/alkali resistant

• Natural EMI shielding properties

• Easy machining – cutting, drilling, tapping and bonding with standard tools

|  |  |

|---|---|---|

| Octagonal | Octagonal | Octagonal |

(5)Primary Applications

• Premium drones & RC aircraft: arms, battery boxes, protective frames

• Robotics & automation: lightweight arm skeletons, square rail covers

• Motorsport & automotive: roll-cage elements, chassis braces, seat frames

• Professional photo/video gear: square jibs, light stands, slider tubes

• Medical equipment: X-ray support arms, operating table frames

• Precision instruments & optics: square housings, lens barrels, lightweight mounts

• Luxury consumer goods: luggage frames, high-end bicycle tubing