LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Product Overview

Our carbon fiber tubes are made from 100% carbon fiber, offering exceptional physical and chemical properties such as lightweight, high strength, excellent rigidity, resistance to acid and alkali corrosion, superior circumferential compressive strength, outstanding longitudinal support, and excellent torsional resistance. These properties make our carbon fiber tubes widely applicable across various areas, including civil, industrial, aerospace, and military sectors.

To meet the specific needs of different industries, we use various grades of carbon fiber and resin materials. We can also enhance the product's physical properties by adjusting the orientation of the carbon fiber layers and the tube's wall thickness. For example, in aerospace and military applications, high-modulus carbon fibers and high-temperature, high-strength resins are typically used to meet the stringent performance requirements.

Below is an introduction to our woven carbon fiber tubing:

(1) Material Structure

• 100% Carbon Fiber + Industrial-Grade Toughened Epoxy Resin

• Inner Layer: High-Strength / High-Modulus Unidirectional Carbon Fiber Prepreg

• Outer Layer: 3K, 6K, 12K Carbon Fiber Woven Fabric, Colored Fiberglass, Carbon Aramid Hybrid, Forged Carbon, Spread Tow Woven

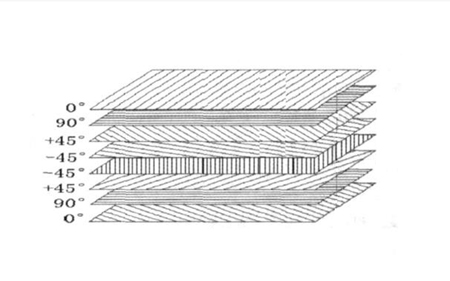

(2) Layup Configuration

• Axial Support: 0°/90° (High Axial Stiffness and Circumferential Strength)

• Torsional Drive: 0°/±45°/90° (Excellent Torsional Performance)

(3) Standard Specifications

• Inner Diameter: 2 mm – 1000 mm

• Wall Thickness: 0.5 mm – 12 mm (Can be made thicker upon request)

• Length: 1000 mm / 2000 mm / 3000 mm

• Tolerance: Inner/Outer Diameter ±0.1 mm

• Surface Finish: Glossy / Satin / Matte / Unpainted

• Appearance Options: Carbon Fiber Twill / Plain Weave, Forged Carbon, Colored Fiberglass, Aramid Carbon Fiber Hybrid, Spread Tow Woven

|  |

|---|---|

| Carbon Fiber Tube | Carbon Fiber Tube with Plain / Twill Weave |

(4)Key Performance Advantages

• Up to 80 % lighter than steel and ~40 % lighter than aluminum at equivalent performance

• Superior torsional stiffness and fatigue life compared to metal tubes

• Completely corrosion-proof – unaffected by seawater, acids, alkalis, UV, salt spray

• Continuous service temperature –40 °C to 120 °C (180 °C systems available)

• Inherent EMI shielding properties

• Easily machined with standard carbide tools (turning, milling, drilling, threading)

|  |

|---|---|

| Roll Wrapped Tube Layup Structure | UD Carbon Laminate Layup Structure |

(5)Primary Applications

• FPV & professional drones: arms, landing gear, tail booms

• Marine: masts, spinnaker poles, oars, flagpoles

• Outdoor & sporting goods: fishing rods, trekking poles, tent poles, avalanche probes

• Robotics & automation: lightweight arms, rollers, drive shafts, telescopic columns

• Automotive & motorsport: driveshafts, spoiler supports, roll-cage elements

• Medical devices: support tubes, X-ray table components

• Photography & film: jibs, sliders, tripod legs

• Measurement & construction: telescopic poles, temporary structures

|  |

|---|---|

| Drone Parts | Sport Goods Components |

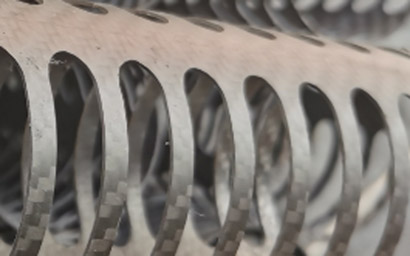

All tubes are manufactured using the roll-wrapping process (table-rolled prepreg on precision-ground mandrels followed by oven cure and centerless grinding) ensuring void-free laminates, perfect inner surface finish, and consistent mechanical properties.

Full customization available: any diameter, wall thickness, color, surface finish, layup design, and secondary machining (tapers, slots, holes, threads, etc.).

Need the ultimate combination of light weight, extreme stiffness, and zero corrosion? Send us your diameter, length, and loading requirements — we’ll return a detailed proposal and firm pricing within 24 hours.