LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Product Overview

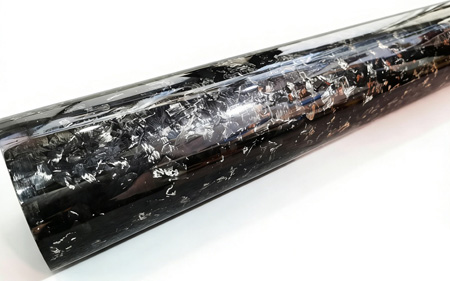

Our forged carbon fiber tubes are manufactured using forged carbon prepreg and unidirectional prepreg materials. These tubes offer excellent physical and chemical properties, including lightweight design, high strength, exceptional stiffness, acid and alkali corrosion resistance, excellent circumferential compressive strength, and outstanding longitudinal support and torsional resistance. However, due to the short fiber structure on the surface of the forged carbon, it lacks the continuous fiber structure found in traditional carbon fibers, resulting in slightly lower tensile strength compared to woven carbon fiber tubes. As such, it is primarily used for decorative purposes or in applications where support requirements are less demanding. Below is an introduction to our forged carbon fiber tubes:

(1)Material Composition

• Outer Layer: Forged carbon fiber prepreg, with optional glitter powder (Gold, Silver, Red, Blue, Green, Purple) added to the surface.

• Inner Layer: Unidirectional carbon fiber prepreg

• Resin: Industrial-grade epoxy resin

(2)Structural Features

• The outer layer features the forged carbon fiber texture (short-cut fibers).

• Available in glitter finish or original carbon fiber color.

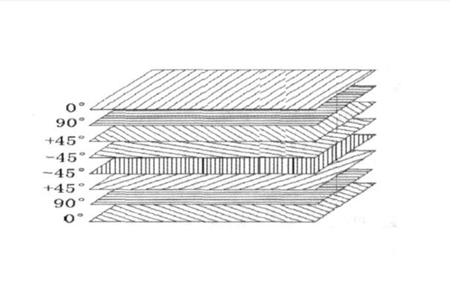

• Internal structure A: 0°/ 90° (high axial stiffness and circumferential strength).

• Internal structure B: 0°/ ±45°/ 90° (excellent torsional resistance).

• Mechanical properties are approximately 90–95% of woven carbon fiber tubes.

|  |

|---|---|

| Forged Carbon Tube | Forged Carbon Tube with color |

(3)Standard Specifications

• Inner Diameter: 8 mm – 1000 mm

• Wall Thickness: 1.0 mm – 8 mm

• Maximum Length: 3000 mm

• Surface Finish: Glossy / Semi-Matte / Matte

• Appearance Options: Original carbon fiber forged pattern, glitter gold, glitter silver, glitter red, glitter blue, glitter green

(4)Performance Advantages

• Up to 80 % lighter than steel and ~40 % lighter than aluminum at equivalent performance

• Superior torsional stiffness and fatigue life compared to metal tubes

• Completely corrosion-proof – unaffected by seawater, acids, alkalis, UV, salt spray

• Continuous service temperature –40 °C to 120 °C (180 °C systems available)

• Inherent EMI shielding properties

• Easily machined with standard carbide tools (turning, milling, drilling, threading)

|  |

|---|---|

| Roll Wrapped Tube Layup Structure | UD Carbon Laminate Layup Structure |

(5)Primary Applications

• Supercar & automotive styling: decorative exhaust shrouds, spoiler struts, interior trim tubes

• Premium drones & RC models: decorative arm sections, tail boom accents

• Professional photography/video: jibs, sliders, tripod tubes

• Gaming peripherals & consumer electronics: stands, accent rings

• Luxury goods & display: canes, light poles, exhibition stands