LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Compression molding Workshop

1. Core Product Offerings

1.1 Custom Carbon Fiber Structural Components

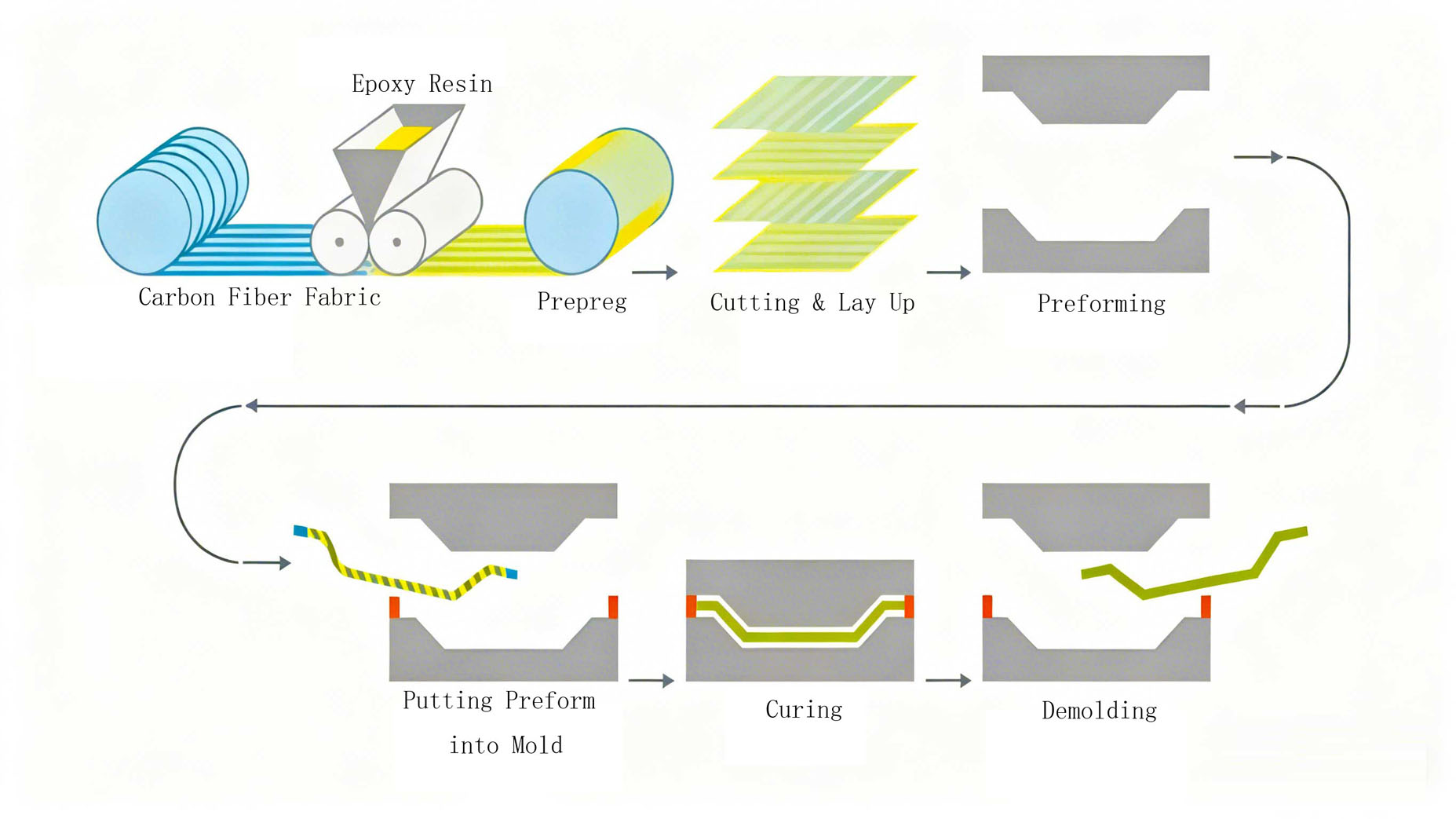

Compression molding remains one of the most proven and widely adopted processes in the carbon fiber industry. We specialize in using this technology for the production of complex, high-strength structural parts serving automotive aftermarket, cycling, industrial machinery, sporting goods, and robotics sectors.

The process utilizes carbon fiber prepreg that is precision-cut, directionally layered, cold-pre-compacted, and cured under precisely controlled heat and pressure. This disciplined workflow consistently delivers components that meet mechanical specifications while eliminating common issues such as inadequate strength or performance variation.

|  |

|---|---|

| Spinner Production | Landing Gear Production |

|  |

| Propeller Production | Pregreg Layup |

|  |

| Compression Machine for Shape Components | Pregreg Hand Layup |

|  |

| Bow Limb Production | Propeller |

1.2 Carbon Fiber & Hybrid Sheets / Plates

Within the same compression molding platform, we operate a dedicated flat-stock production cell equipped with four multi-daylight hydraulic presses. These presses are configured specifically for panel manufacturing and enable exceptional control over thickness tolerance, flatness, surface quality, and internal laminate properties.

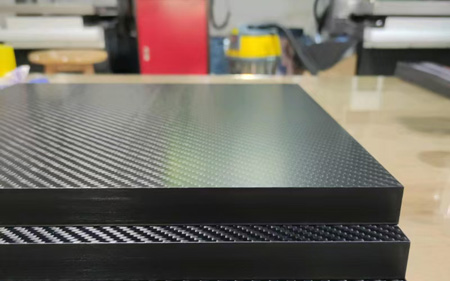

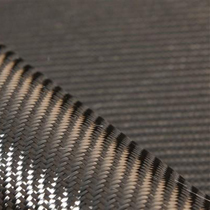

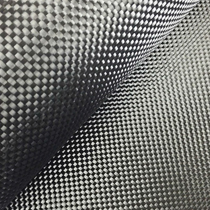

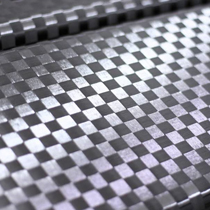

Sheets are built from combinations of unidirectional carbon/glass prepreg, woven carbon (plain/twill), forged carbon, colored glass, and aramid/carbon fabrics. The resulting quasi-isotropic or tailored layups serve as high-performance rc car chassis plates, machine guards, drone frames, knife-handle material, and precision substrates.

|  |

|---|---|

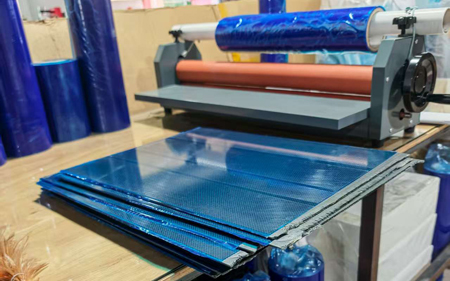

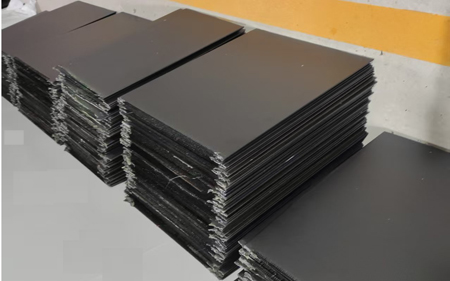

| Compression Machine for Plate Production | Pregreg Preparation |

|  |

| Carbon Plates | Thick Carbon Fiber Plate |

2. Production Sequence

1. Material Preparation – CNC plotter cutting of prepreg kits to exact dimensions

2. Directional Hand Layup – Plies collated and placed in steel tooling according to validated stacking sequences

3. Cold Pre-Compaction – Room-temperature consolidation to remove air and lock in thickness

4. Heat-and-Pressure Cure – Multi-daylight presses execute resin-specific temperature/pressure profiles.

5. Cooling & Demolding – Parts held under pressure while cooling below 50 °C to minimize residual stress and distortion

6. Final Finishing – CNC trimming, surface sanding/polishing, and protective coating as required – delivered assembly-ready

3. Core Client Value

Our mission is to accelerate your development timeline and reduce risk.

Whether you require contoured structural parts or flat panels, you simply provide 3D files or detailed specifications. We manage the entire program in-house:

• Design-for-manufacturability review & layup optimization

• Tooling/mold design and fabrication

• Prototype validation

• Stable, repeatable volume production

This integrated approach shortens lead times, eliminates multi-vendor coordination, and significantly lowers trial-and-error costs.

4. Process Characteristics

Key Advantages

• Excellent specific strength and stiffness, direct metal replacement potential

• Highly repeatable mechanical properties and cosmetic finish

• Efficient material utilization and low scrap rates

• Full traceability and batch-to-batch consistency

|  |  |  |

|---|---|---|---|

| Twill Weave | Plain Weave | Forged Carbon | Spread Tow Woven |

Objective Notes

Compression molding is inherently a single-cavity-per-cycle process. For larger volume programs we mitigate this by:

• Building and running multiple tool sets in parallel across our four presses

• Careful production planning and transparent scheduling

Any unforeseen material or environmental variations are communicated immediately, and contingency options are presented without delay.

Our compression-molded components and sheets are currently trusted by customers in automotive modification, high-end sporting goods, industrial automation, and competition-grade RC modeling. If you have requirements for contoured carbon fiber parts or precision flat stock, please share your drawings or performance targets. We will respond within 24–48 hours with a detailed manufacturing proposal, sample plan, and firm pricing.

We look forward to becoming your reliable compression molding partner.