LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

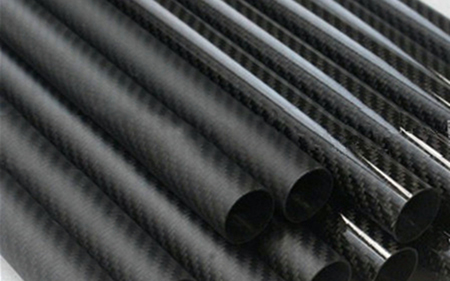

Roll-Wrapped Carbon Fiber Tube Workshop

Professional Custom Tubing Solutions

1. Core Focus: Your Reliable Partner for High-Performance Carbon Fiber Tubes

Our dedicated roll-wrapping facility specializes in custom carbon fiber tubing for drone frames, marine masts, telescopic poles, lifting columns, fishing rods, trekking poles, camera rigs, robotics, and virtually any application requiring lightweight, stiff, and torsionally strong tubular components.

From structural supports to high-torque drive shafts, standard sizes to extreme custom specifications, we deliver tubes that meet your exact mechanical, dimensional, and aesthetic requirements.

2. Proven Roll-Wrapping Production Process

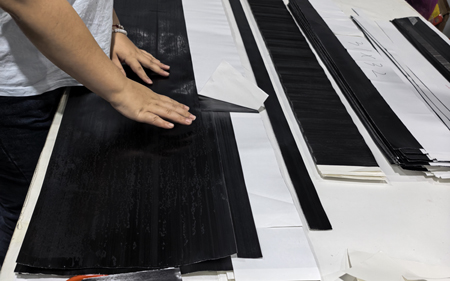

(1)Mandrel & Material Preparation Precision-ground stainless steel mandrels are coated with release agent. Unidirectional, woven, and hybrid prepregs are cut to exact calculated dimensions.

(2)Precision Layer Wrapping Using automated and manual rolling tables, each ply is wrapped at the specified angle and tension. Constant pressure ensures zero trapped air and perfect interlayer bonding.

(3)Heat-Shrink Tape Application BOPP or polypropylene shrink tape is tightly spiral-wrapped to apply uniform consolidation pressure during cure and prevent resin bleed.

(4)Controlled Oven Cure Tubes cure at 120 °C for 1.5–2 hours (longer for wall thickness >5 mm) in calibrated ovens with excellent temperature uniformity.

(5)Post-Processing Tape removal → mandrel extraction → end trimming → centerless grinding/sanding → final clear-coat or color painting → quality inspection.

|  |

|---|---|

| Carbon Material Preparation | Mandrel Preparation |

3. Customization Capabilities & Technical Features

Structural Design Options

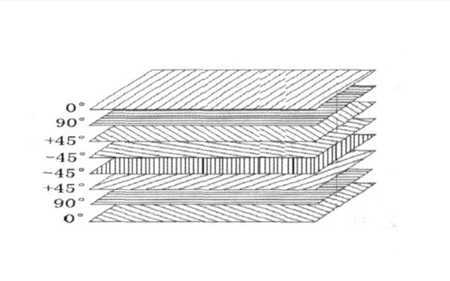

(1)Push/Pull & Static Load Applications

0°/90° layups: maximum axial stiffness and hoop strength (ideal for landing gear, tail booms, support arms, telescopic poles).

(2)Torsional & Drive-Shaft Applications

0°/±45°/90° schedules: optimized torque transmission (marine masts, robotic arms, high-performance drive shafts).

(3)High-Temperature Environments

Special high-Tg epoxy prepregs for continuous service above 100 °C.

|  |

|---|---|

| Roll Wrapped Tube Layup Structure | UD Carbon Laminate Layup Structure |

Material Selections

(1)Inner Layers (strength & weight control)

High-modulus or intermediate-modulus unidirectional carbon fiber; optional glass or aramid hybrids for cost or impact resistance.

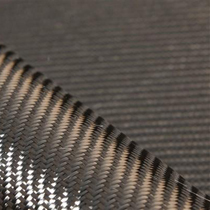

(2)Outer Layers (appearance & added function)

3K/6K/12K twill or plain-weave carbon, colored glass fiber, aramid/carbon hybrids, forged carbon finish, or silver-plated glass for subsequent colored painting.

|  |  |  |

|---|---|---|---|

| Carbon Fiber Woven Fabric | Color coated Fiberglass Fabric | Forged Carbon Fiber Pattern | Carbon /Aramid Hybrid |

Dimensional Precision

(1)Standard mandrel library covers most common IDs

(2)Custom mandrels available for any diameter

(3)Maximum single-length capability: 3000 mm (longer tubes via precision bonding)

(4)Wall thickness uniformity and roundness maintained through calculated ply sizing and controlled rolling tension

(5)Finished ID/OD tolerance: ±0.1 mm (tighter on request)

Surface & Color Options

(1)Gloss, matte, or natural “no-paint” finish

(2)Full-color custom painting over silver-plated glass fabric base layer

(3)UV-stable clear coats for outdoor applications

|  |

|---|---|

| Gloss / Satin / Matte Finish | Custom Colored Finish |

4. Key Problems We Solve for Our Customers

(1)Precise torsional and bending performance through engineered fiber orientation

(2)Tight ±0.1 mm tolerances for perfect fit in telescopic or sliding assemblies

(3)Full aesthetic customization for consumer-facing products

(4)Consistent quality from prototype to high-volume production, minimizing field failures and warranty costs

5. Why Choose Us

(1)Experience – 23 years of composite manufacturing and a roll-wrapping team with decades of hands-on expertise

(2)In-House Control – Mandrel production, prepreg storage, rolling, curing, and finishing all under one roof for fast turnaround and full traceability

(3)True One-Stop Service – Requirements discussion → structural design → rapid prototyping → volume production → post-delivery support, with a dedicated project manager from day one

Ready for perfectly engineered carbon fiber tubing? Send us your specifications or 3D files and we’ll return a detailed technical proposal and firm quotation within 24–48 hours.

We look forward to becoming your long-term roll-wrapped tube partner!