LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

Pultrusion Workshop

1. Our Workshop

Pultrusion is one of our longest-standing and most refined processes — a true core competency built over 23 years in the composites industry.

Our facility runs five modern pultrusion lines capable of high-volume production of both carbon fiber pultruded profiles and glass fiber pultruded profiles. The result is industry-leading consistency, short lead times, and highly competitive pricing for standard and fully custom shapes.

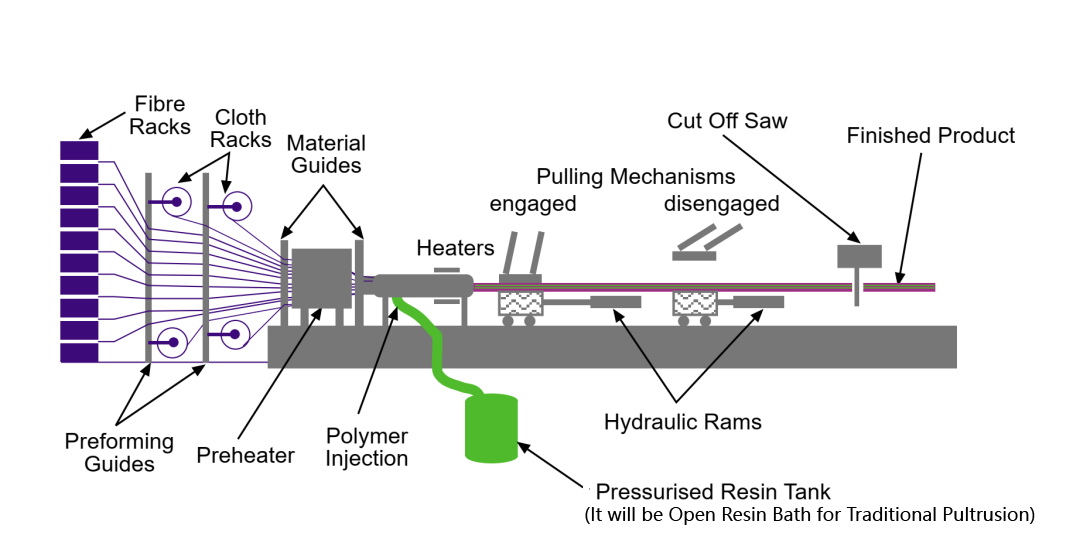

The pultrusion process pulls continuous unidirectional fibers through a resin bath, into a heated die (120–160 °C) where the resin cures, and then through a cooling zone before precision cutting. Because the fibers are perfectly straight and continuous, the finished profiles deliver exceptional tensile and flexural strength in the fiber direction and can theoretically be produced in infinite lengths — ideal for long, straight structural components.

|  |

|---|---|

| Pultruded Profiles Production Line | Fiber Racks and Resin Tank |

2. Pultrusion Process

1. Fiber Wet-Out – Continuous unidirectional rovings/creels are pulled through an open resin bath for full impregnation

2. Pre-Forming & Die Entry – Guides align fibers precisely before entering the heated chrome-plated die

3. High-Temperature Cure – Die temperature profile cures the resin in seconds while maintaining exact cross-sectional shape

4. Cooling & Solidification – Water or air cooling locks in geometry

5. Precision Cutting – Flying cut-off saws deliver parts to your exact length (±0.5 mm typical)

|

|---|

3. Core Supply Capabilities

• Stock Library: about 400 standard profiles ready for immediate production

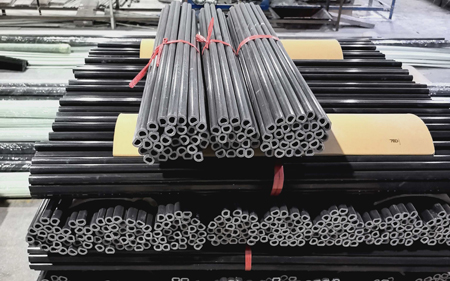

• Solid round rods

• Solid square/rectangular bars

• Round & rectangular tubes

• Flat strips

• Oval tubes

• I-beams, C-channels, angles, and custom open sections

|  |

|---|---|

| Carbon Fiber Pultrusion | FiberGlass Pultrusion |

• Materials

• Standard: Carbon fiber or E-glass + corrosion-resistant vinyl ester resin

• Optional: Epoxy resin systems (higher stiffness & temperature resistance)

• Color: different color as red、blue、yellow、gray、green on request

• Custom Dies: Free tooling development for non-standard cross-sections (subject to reasonable minimum order)

Low material waste, mature process control, and economies of scale give us outstanding quality stability and market-leading value.

4. Technical Characteristics & Objective Guidance

Key Advantages

• Outstanding longitudinal tensile and bending strength

• Extremely lightweight (carbon versions especially)

• Superior stiffness-to-weight ratio compared to metals and most plastics

• Excellent corrosion, fatigue, and chemical resistance (vinyl ester systems)

• Fully customizable cross-section, color, and length

• Seamless continuous production = zero length limits

Known Limitations

• Lower hoop (radial) strength than roll-wrapped or filament-wound tubes due to unidirectional fiber architecture

• Epoxy-based production runs slower than vinyl ester — lead times are adjusted accordingly for higher-performance grades

We always recommend the optimum process (pultrusion vs. roll-wrapping vs. other) based on your mechanical requirements and budget.

5. Primary Markets & Applications

Our pultruded carbon and glass fiber profiles are trusted worldwide in:

• RC aircraft & drone reinforcement

• Tent & shelter poles

• Kite spines & frames

• Flagpoles & banner supports

• Umbrella & mosquito-net frames

• Sporting goods (arrow shafts, hockey sticks, vaulting poles)

• Agricultural greenhouse structures

• Lightweight conveyor components

• Corrosion-resistant industrial framing

• Telescopic tool handles and cleaning poles

Ready to Get Started?

Whether you need off-the-shelf profiles delivered next week or a brand-new custom section developed from your drawings, contact us today.

We offer free die design and quotation within 24–48 hours and sample lengths for qualification.

23 years of pultrusion expertise — stable quality, competitive pricing, and genuine partnership.

We look forward to supporting your next project!