LenRun

23 Years Experience·Carbon Fiber Products Manufacturer

Excellent Services·One-Stop Product Solution

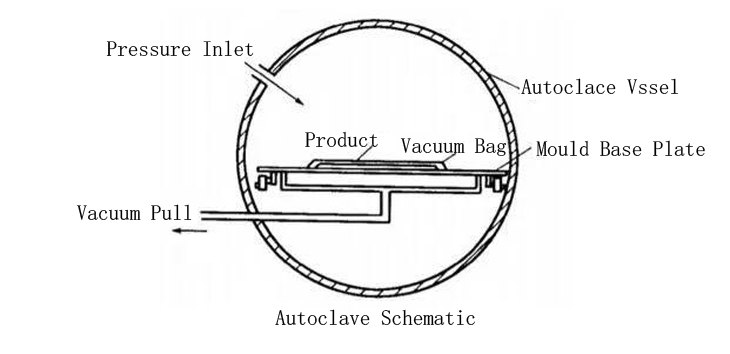

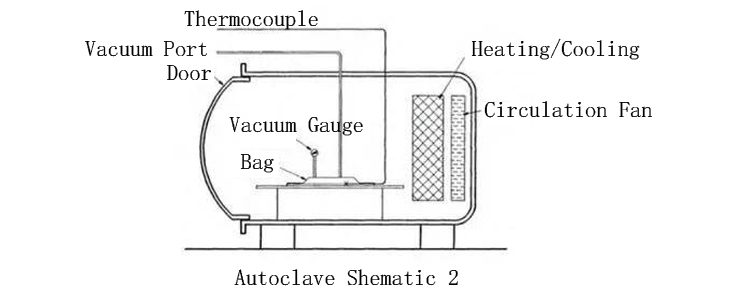

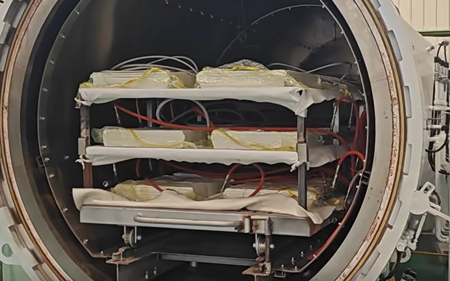

Autoclave Processing Workshop

(A)Core Positioning

Custom Manufacturing Center for Large-Format Carbon Fiber Products

Our autoclave facility specializes in the custom production of large-format, complex-geometry, high-precision cosmetic components, primarily serving automotive exterior and aftermarket parts, drone fuselages, marine structural elements, large carbon fiber plates/sheets, and other applications demanding superior surface weave appearance, texture, and uniform load distribution.

Leveraging mature autoclave processing technology with tightly controlled parameters (temperature 80–180 °C ±5 °C, pressure 0.8–2.0 MPa ±0.05 MPa), we provide end-to-end solutions from design optimization to volume production, effectively addressing the key challenges of forming large composite parts: processing difficulty, inconsistent properties, and surface defects.

|

|---|

(B)Production Workflow

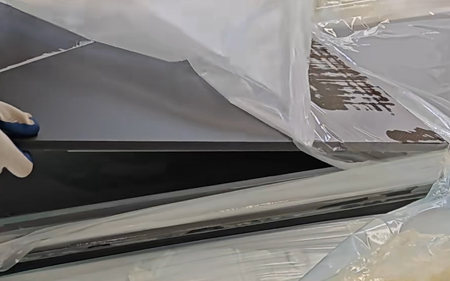

(1) Precision Material Preparation – Optimized ply kits cut from 3D data; material scrap kept <5 %.

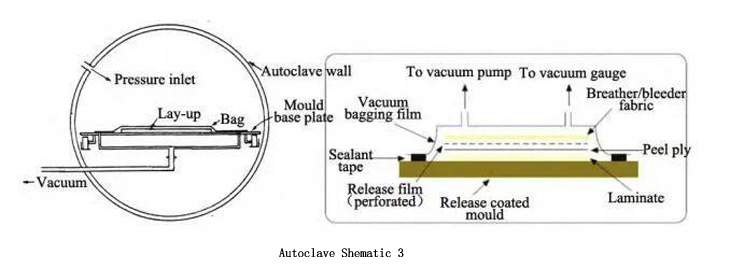

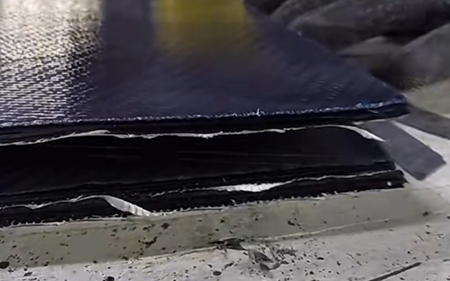

(2) Directional Layup & Debulk – Layer-by-layer placement with intermediate vacuum debulking to remove air and improve consolidation.

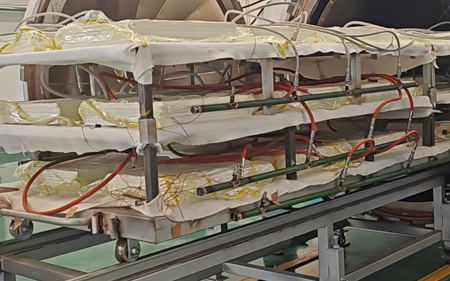

(3) Vacuum Bagging & Leak Check – High-temperature film bagging, pulled to –0.095 MPa and held 20–30 min for leak verification.

(4) Precision Cure – Customized profile (typical epoxy: 120 °C / 2 h / 1.2 MPa) with active air circulation for uniform resin cure.

(5) Controlled Cooling & Demolding – Parts cooled below 50 °C before removal to prevent distortion from resin shrinkage.

(6) Final Finishing – High-precision trimming, sanding, and coating as required—delivered assembly-ready.

|

|---|

(C)Key Process Advantages

(a)Core Technical Strengths

1. Uniformity Assurance: High-velocity circulating hot air and gas pressurization maintain vessel temperature variation ≤ ±3 °C, with pressure applied evenly across part surfaces. This effectively resolves issues in large components (up to 2000 mm × 4000 mm) such as uneven stress distribution, localized weakness, and irregular weave patterns, improving first-pass yield and minimizing rework.

2. Precision Control: Real-time PLC monitoring of temperature, pressure, and vacuum, combined with custom steel, aluminum, or high-temperature resin tooling, delivers dimensional accuracy of ±0.1–0.5 mm and surface roughness Ra ≤ 0.8 μm, significantly reducing secondary finishing requirements and associated costs.

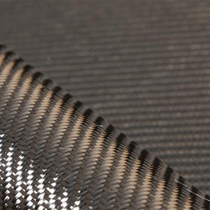

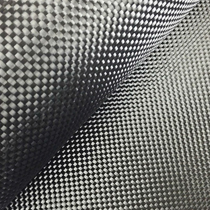

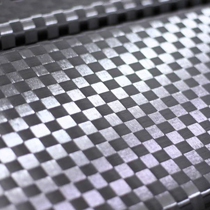

3. Material Flexibility: Compatible with 3K/6K/12K carbon fiber, spread-tow carbon fiber, forged carbon fiber, fiberglass, and aramid prepregs in woven or unidirectional form. Supports lightweight foam cores, colored fabrics, matte/gloss finishes, and other cosmetic options to meet diverse aesthetic and performance needs across visible and high-end equipment applications.

|

|---|

(b)Precise Comparison with Compression Molding

(1) Application Scenarios

1. Autoclave: Ideal for large-format and complex shapes such as automotive panels, drone bodies, large luggage shells, marine structures, and large carbon fiber sheets.

2. Compression Molding: Better suited to small, high-strength structural parts like bicycle pedals, phone cases, drone landing gear, and propellers.

3. Selection Guidance: For volume production of large visible or structural components, autoclave processing avoids the size constraints of compression molding and reduces tooling costs. It is the preferred choice for parts >500 mm or where surface finish and dimensional consistency are critical.

|  |

|---|---|

| Shaped Components | Car Parts |

(2)Core Performance Characteristics

1. Autoclave: Excellent size scalability, uniform surface quality, and balanced stress distribution – ideal for larger parts requiring high cosmetic and dimensional consistency.

2. Compression Molding: Superior localized strength, though weave alignment is more difficult to control precisely – best for small parts prioritizing structural performance.

|  |

|---|---|

| Pregreg Preparation | Load into Autoclave for Cure |

(3)Objective Notes & Mitigation Measures

1. Process Limitations: Higher initial equipment investment, longer per-cycle times, and consumption of vacuum bagging consumables (bags, breather) result in greater energy and time use compared to compression molding.

2. Customer Assurance: For high-volume orders, we employ parallel autoclave runs and standardized tooling to shorten lead times by 20–30 %.

|  |

|---|---|

| Remove from autoclace | Demolding |

(D)Why Partner with Us?

• Technical Confidence – 23 years of composite experience and a dedicated autoclave team that rapidly resolves common issues (warpage, surface imperfections, etc.).

• Capacity Assurance – Three autoclaves of different sizes enable parallel runs and flexible scheduling to meet your deadlines.

• Service Excellence – Complete turnkey support: 3D optimization → tooling → prototypes → volume production → after-sales follow-up, with a single point of contact throughout.

|  |  |  |

|---|---|---|---|

| Twill Weave | Plain Weave | Forged Carbon | Spread Tow Woven |

If you are facing challenges with large carbon fiber components—forming difficulty, cost control, or quality consistency—simply send us your 3D files. We will provide a free detailed manufacturing proposal and accurate cost estimate to help you achieve superior products and stronger market positioning.

We look forward to supporting your next project.